B33

vos tantum postulo unus cylinder si is est amplus satis

Now there's one bike I've always wanted, and that's a 500cc BSA B33, but not just any B33, the one with the alternator and set in a swing arm frame. This was as far as BSA went with the pre unit singles, and they were in production up until about 1962. Considering they didn't start producing this model until 1959, and when they did, they made more of the 350cc B31 models, then as you can imagine they don't come up for sale very often. April 2006 and I happen to see an alternator B33 for sale on eBay, what's more it was local. Friday April 14th saw me heading over to Burton on Trent to take a look at this bike before bidding on it. OK, so it wasn't perfect, but it all seemed to be there - oh for the joys of X-ray vision. I won the bike for the grand sum of £1555. On Thursday April 27th I broke up for holiday, but first of all I went and picked up my B33.. . . . . and so the story begins.

Right. First thing I did was to remove the engine and gearbox. Get a rolling frame first, then concentrate on the bits that make it go. Whilst pulling the engine out it seemed as though this bike had suffered rather a lot of accident damage. Both inner and outer primary chain cases had been stitched back together and a very thick cork gasket sandwiched between them to prevent any leakage. Oh what joy. I now have to find a set of alternator chain cases - this should prove interesting to say the least. Not only were the chain cases scrap, but it seemed the frame had suffered similar damage. Time to add a new frame to the shopping list. I removed the front end next. Oh dear, the bottom yoke had been welded back together - both fork stanchions had also been snapped and re-welded. The shopping list now also contained a complete front end. Just for good measure, the swing arm was both bent and twisted. In short, it looked like this bike had been struck in the rear with extreme force and pushed into what ever was in front of it. Under normal circumstances an accident like this would see the bike totally scrapped, but whatever country this bike came from had more of a make do and mend culture.

The original oil tank was dented, so it was eBay to the rescue and a fairly dent free tank was obtained for the very reasonable sum of £16. It seems the reason the tank was so cheap was the oil return stand pipe was missing. Ah well, time to cut the tank open, then make and fit a new stand pipe. We happened to find a mystery object living inside the original tank. A wooden handle with what looked like a sharpened length of welding rod attached. Whatever purpose it could have served will remain a mystery.

October saw me at the Stafford bike show. I came home with a rolling B31 frame complete with gearbox - that was goodbye to £400. This frame was in far better condition than the original, but still needed some new frame tubes fitting in the bottom cradle - nothing that another £150 wouldn't put right. Now this spending money lark was getting serious, so I decided to buy a complete bike and cannibalise it for parts. December saw me heading over to the Isle of Anglesey and coming home with a very nice B31, so that was the best part of £2000 gone. As it turned out, the B31 was far too nice to use for spares and I ended up registering it for the road. The tale of the B31 can be found in the "BIKES" section on this website.

So ended 2006 and I was nowhere near getting so much as a rolling chassis, let alone a complete bike.

2007 - the saga continues.

January saw me at the Donington bike show ( can you see a theme forming here ? ) where I wandered around buying various new bits and pieces. I came back clutching fork top nuts, magneto pickup unit, spare collar for pick up unit, set of Whitworth spanners, dynamo regulator, full set of 12 volt bulbs, 12 volt battery, side stand, twist grip, plug cap, spark plug and a petrol tap. Ok, so the magneto and dynamo stuff was for another bike, but I still ended up participating in a major spend-fest. Later the same month I managed to get a set of primary chain cases. The outer case had been repaired, but it would not be visible by the time I had finished with it, the inner case was brand new - a bargain at £90. More bike shows followed, Malvern and Stafford, and more bits were bought. I bought a complete B31 bottom end from eBay, nice and local in Walsall and only cost £65. This bottom end was to come in very useful later on. I decided a disc brake front end would be far more practical than the original BSA / Ariel brake, so I bought a Triumph T140 front end - £300. Of course, this needed head bearings, SRM did a taper roller bearing set - £63. The front end is no good without wheels, so both wheels were rebuilt with new stainless rims and spokes - that took care of another £450. Tyres and tubes ate up another £114. The bent swing arm was replaced, courtesy of Vale-Onslow, who had a brand new one for £80 or a second had one for £40. I decided on the second hand one, only to find the wheel spindle slot had been machined out wider than original. Ah well, time for a bit of welding and re-machining. Stainless steel mudguards came next - the best part of £150. A new petrol tank set me back £275, followed by £200 for painting. Let's not forget the £85 for a new seat ( the cover of which started to split before the bike had covered 3000 miles, so we add another £30 for a new seat cover ). Oh yes, a speedometer would be nice, £140 for a Smiths Chronometric, then another £117 to have it reconditioned and calibrated. Right, we might just have enough bits to build a rolling chassis now.

2008 - time to make a start on the engine

Right, we now have a rolling chassis, give or take a few things, but we have enough to make a start on something to put in it. Oh dear, the engine was in about as good a condition as the rest of the bike. The main bearings had spun in the cases, the big end nut had been done up using a chisel, the main shafts had been centre punched to give a better fit in the bearings, the cam followers were badly scored, the oil pump was shot, in short, the engine was fit only for scrap.

Remember that B31 bottom end that I paid £65 for on eBay ? Well now it was time to find a use for it. The only difference between the 'normal' dynamo equipped engines and the alternator ones is the size of the hole where the mag-dyno fitted. On the alternator models this hole was considerably larger to allow for the distributor to fit. Time to bring the milling machine into play. The crankcase was bolted to the bed of the miller and the hole 'clocked up' to find the centre. A few minutes work with a boring bar and the hole was now large enough to accommodate the distributor. The now modified crankcase was machined again, this time in order to re-number it. By filling the machined part with aluminium weld, then ageing it using a very coarse shot blast machine it was made fit for use once more.

The oil pump was replaced at a cost of £100. Of course, the new oil pump had been made to such poor tolerances as it leaked oil back into the crankcase. Time to pull the thing apart, re-machine it to within a few thousands of an inch, then lap it to size. This went a good way to preventing the 'wet sumping' associated with worn or out of tolerance oil pumps but the problem never went away completely until I fitted an 'anti wet sumping valve' - which cost another £36.

The crankshaft assembly was total scrap. Both the drive side and the timing side shafts were scored, the crankpin holes in the flywheels were oval and the big end was scrap. Now I did have a set of flywheels that came with the eBay B31 engine, but sadly B31 flywheels are lighter than B33 flywheels. Luckily a set of what we thought were B33 flywheels turned up at Vale-Onslows - I forget how much they cost but they included a 'free' con rod. Having now got a set of flywheels, the entire thing was taken to Alpha Bearings for a new crankpin and big end, a new small end, two new drive shafts and the whole plot assembled into a working crankshaft. This took about five or six weeks and cost £550. The crankshaft ain't much good without some bearings for it to spin in, so a new set of main bearings were fitted - goodbye to another £55. I might as well do something with the cylinder barrel whilst I'm at it. One of the fins was broken, so a new cast iron fin was obtained and shaped to fit - this was then welded to the barrel. I found a Hepolite piston and cylinder liner on eBay, so that was another £75 up the swanee. The barrel, liner and piston were sent off to be fitted - oh dear, that liner will not fit into that barrel, and the piston has too low a compression height. Time to order the correct piston from Thorntons, up at Shrewsbury, so that's another £85 on the bill. At least the fin fitted.

July 5th, and time to put the bottom end together.

Heated up the crankcases and fitted the main bearings. Put the two halves

together and there was minimal end float in the crankshaft. So far, so

good. It

The crankshaft was sent back to Alpha Bearings for the correct timing side shaft to be fitted. By the time the crankshaft came back, the barrel and piston were done and dusted - following a £30 bill for the new liner. Because of the new long throw crank, the skirt of the piston needed to be machined down so that it did not foul on the flywheels. Time once again for the milling machine and the boring bar.

Good grief - does this mean the bottom end is now complete ? Yes, I think it does.

Let's take a look at the cylinder head. Hmm, fins broken, rocker cover threaded hole broken out, valves and valve guides worn out, rocker arms badly worn and the rocker arm spindles had seen better days. . . . so that will be a complete head rebuild then. Once again most of the parts were picked up at various shows and auto-jumbles, with the rocker spindles coming from Yeomans - a very good find as they were unused - we still had to sort through a great box of various bits to find 'em though. New fins were made and brazed into place, and the broken hole was brazed up and then drilled and tapped. I also managed to find an exhaust rocker cover, complete with valve lifter. New over size valve seats were fitted so that the largest valves possible could be used, this should increase the performance a bit - not that B33s ever had any performance to start with. Of course, the new valve seats were made oversize in all directions, so they had to be machined down so they did not intrude too much into the ports, which were also polished and slightly gas flowed. I didn't keep an exact list of how much the head cost to refurbish, but I would guess at around £200

This brings us up to November, and the engine is just about finished - time to sit it in the frame and think about fitting some kind of transmission.

The engine's done - now for the transmission.

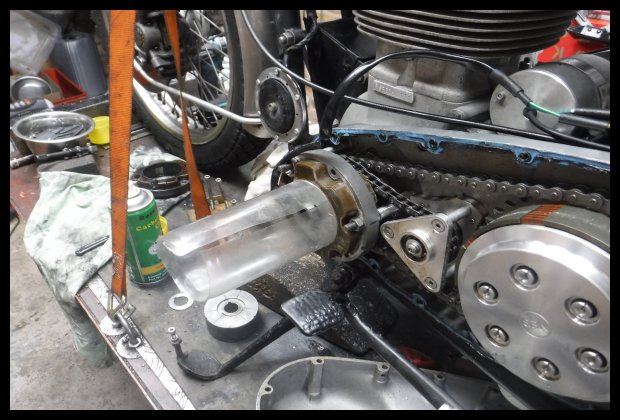

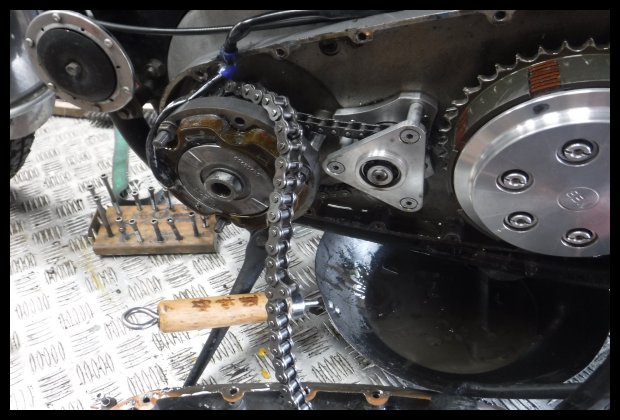

Sadly the gearbox was in the same state as the rest of the bike, but luckily the rolling frame I bought at the Stafford show last year came complete with one. Time to try and make one good one out of two not quite so good ones. Most of the actual gears were not too bad, with the exception of the kick start mechanism which was totally shot in both boxes. Nothing that £110 didn't put right. All the bearings were replaced too, as was the final drive sprocket and chain. The gearbox casing was also broken, so that went away to be aluminium welded, and then got machined back into shape. The clutch operating arm was sent off to be polished and re-chromed. I would have preferred stainless steel as this not only doesn't rust, but would have been in keeping with all the other fasteners and fixings that were on the bike. New gear lever and kick start lever were also purchased. All in all, including the stainless gearbox adjuster and the rear wheel spindle it cost around £300 to obtain a decent working gearbox - although it may not be working as well as could be expected, as I came to find out later. A bit of nifty work with a file and a new drive key was made for the clutch. Speaking of clutch, I decided a belt drive option would be the favourite ( ever thought you may have made the wrong choice ? ) so off went £530 and back came a shiny new clutch assembly. The clutch basket itself was fine, a pity the drive belt was the wrong size and I didn't like the look of the primary drive pulley. The belt was changed with no problem, as for the pulley it was made to fit a Triumph rather than a BSA. By turning the pulley back to front and re-fixing the belt guide it was made to fit, although I didn't think it was a good enough fit. As it turned out I was correct - there is .030" difference, but we fitted it anyway, it can always be corrected later on.

Things were looking good, and following a new £70 carburettor and a jury-rigged exhaust system, something remarkable happened on December 28th, 2008 . . . . . the engine ran for the first time.

2009 - It all starts coming together nicely.

The start of January saw me at the Donington show, coming back with more B33 bits - fifty inch speedometer cable, which as it turned out was five inches too long, so that will have to be changed, a couple of stainless headlight mounting bolts and the odd grommet or two. Next job was wiring the bike up, at least that didn't cost me much in the way of materials, all I had to buy was the battery itself. I also fitted a neat little device which replaced the ammeter. This consists of an LED which changes colour depending on the voltage present, it also dims at night so that it doesn't dazzle you. Even costs about the same as an ammeter at £26. The Malvern show came next, along with mirrors (£15) footrest rubbers (£5.50) and another load of stainless steel fasteners. The Telford show was the following weekend. I managed to get the correct speedometer cable and a few bits for the headlight. Just to round the month off I ordered the exhaust system - £170, from Armours - stainless steel of course. Speaking of stainless steel, a chain guard would be a useful thing to have. . . .so we made one out of brown paper . . .as a pattern . . . then made one out of aluminium . . . to prove it fits . . . then made one out of stainless steel . . . Thanks Pete, you did a cracking job.

I ended up down in Shepton Mallet for the classic bike show and got the last few remaining bits - tank badges, knee pads, knee pad brackets and a few other things. Right - let's put it all together and take it for MOT. The last day of February, and the B33 passed the MOT.

The first day of March, and the B33 goes on its maiden voyage. First off, the speedometer reads fast, so that has to be sent back to the place that calibrated it. Something doesn't sound right in the back wheel - it turned out that the securing ring holding the wheel bearing wasn't fully tightened, so that was an easy fix. The distributor bolt wasn't tight, so the dizzy turned slightly and advanced the timing, this resulted in the engine running too advanced and getting hot. Luckily I know the feeling of an engine which is about to seize, so was able to stop before any damaged occurred. It didn't take much to retard the timing a bit and tighten the dizzy bolt. What I didn't like was the sound that the primary drive pulley was making. It was just too loose a fit on the splines. Nothing for it but to take the pulley off and send it back to Tony Hayward, who supplied the clutch in the first place. Following a few phone calls, Tony sent me a pulley blank so that I could get my own hole broached in it. The blank he sent me was no use whatsoever for an alternator BSA. Tony Hayward does excellent Triumph belt drive conversions, but I'm afraid he has not got a clue when it comes to alternator BSAs. I bought myself a 10mm pitch X 28 tooth reduced backlash pulley from HPC gears, at a cost of £53, then paid another £40 to have the hole broached in it. Even this hole could have been done to closer tolerances, but at least I now had a working primary drive. Not having 100% faith in this belt drive I decided to buy a complete primary chain drive, more as an insurance thing than anything else, so that saw me spending another £400 at Vale-Onslows.

I happened to spot a brand new dizzy at the Malvern show, so £40 later and it was mine. It got fitted the following weekend. Ah, my speedometer has come back, all calibrated . . .again. The Stafford show - and I bought a CNC aluminium sump plate, this has the advantage of having a drain plug fitted, which always comes in useful should the bike start wet sumping - £36 well spent.

The black B31 which I bought in order to cannibalise was sold at the Wistanstow bike show, so that put £2300 back into the funds.

May 13th - and the B33 is ready to go back on the road again. This time all went well, apart from the battery, which was bought brand new only three months ago, had decided to fail. The shop replaced it with no bother.

There still seems to be some kind of bearing failure, more a thing you can feel, rather than describe. I pulled the gearbox apart, but apart from one circlip which wasn't seated, there didn't seem anything wrong. The back brake operating rod, which is made of 6mm stainless steel, needs to be thicker - it just flexes under pressure. Just for good measure, the bike jumped its exhaust pushrod whilst passing junction 2 of the M5. The last four miles were done in the back of a van - how embarrassing.

Took a nice long test ride over to Newark - managed to jump the exhaust pushrod again on the way back. A bit of spanner twirling on the side of the road and we were under way again. I took the top off the engine the next morning just to make sure nothing nasty had happened to the valve gear. I love the way these engines come apart - only four bolts hold the top end in place. Having put the engine back together again I put a good 280 miles on the clock, going on a scenic ride to the coast and back via the Elan Valley dams. The bike never missed a beat, and returned an amazing 90 miles to the gallon.

The next little snag seemed to be a split oil tank. Luckily the tank comes off dead easy, and it wasn't split it was just one of the banjo bolts not fully tightened.

June 12th, and the bike was about to cover its first 1000 miles. I took a ride up to the summit of Clee Hill, and as I came back down I watched the clock roll over to 1000 . . . it then carried on rolling over to 2000, then 3000, in fact it didn't stop until it had covered 15,000 miles. As you can imagine, the clock got sent back to Speedograph once again. They were most apologetic and returned it with the correct mileage being displayed. I'll tempt fate, I haven't had any more hassle with the clock since. There was an issue with the bike wet sumping despite being fitted with a new oil pump. This was cured by fitting an "anti wet sumping valve" - a nifty little device which screws into the feed side of the oil pump and prevents oil flowing back when stopped. It does exactly what it's supposed to, and cost all of £36. Whilst touring on holiday I had the battery fail again. This time I didn't bother with a cheap replacement, I paid the difference and fitted a Yuasa - £28 as opposed to around £15 for a cheap one.

Another "milestone" in the B33 story happened on July 19th. Myself and Andy set off for Jack's Hill cafe. Our first stop was the old BSA factory at Armoury Road, then a scenic ride down to Towcester and the "Ton-up day" at the cafe. We had excellent weather all the way there, but once we arrived the heavens opened up. After 1500 dry miles the B33 finally got wet, seriously wet. Ah well, it had to happen sooner or later.

In September two BSAs set off for the Lake District. Andy on his Starfire, and myself on the B33. We had a most excellent holiday, with the bikes covering just shy of 1000 miles - all trouble free may I add. It looks like the B33 was all set to do what a BSA does best . . . . . sadly that wasn't to happen. The following month a careless car driver almost took off my left leg, luckily I was not riding the B33 at the time, but it's now twelve months since the accident and I still can't walk, let alone ride a bike. I hope to update this page once I'm able to ride again . . . . October 2010 and counting.

2011 - after 17 months I get back on the B33

Well, it's now the beginning of June, 2011, and I've just got back from taking the B33 for MOT. Yes - I can now ride the bike once again. OK, so there's a plastic drainpipe fitted on the front forks which serves as a carrier for my crutch, but the only other modification was a small lug welded on the foot of the side stand which enables me to lower the stand easier with my dodgy left foot. Just for good measure it's also the warmest day of the year so far - I hope this is a sign of things to come.

Due to the aforementioned left foot, I decided that the rear brake could do with being more efficient. I did toy with the idea of fitting a disc rear wheel, which if nothing else would match the front one. In the end it seems BSA had the best idea - my rod operated system just didn't work well. The rod would both flex and twist, and the BSA rear brake ain't brilliant at the best of times. So it was time to convert back to cable operation - OK, this meant either a total strip down to a bare frame, or just repaint the area where the cable stop had to be welded. I opted for the easy option, and out came the Smoothrite. I've since obtained a later style brake plate which has the cable stop cast into it, as opposed to a bolt on lug which fits on the lower part of the brake plate - this means the cable has a neater route and the brake operating arm faces towards the top - this will be fitted the next time I have cause to remove the rear wheel.

The Smiths Chronometric speedometer, which had earned the nick name of "The Precious Thing" due to the amount of money that had already been thrown at it, decided to fail. I took it apart to see if there was an obvious fault . . . the only thing obvious was the fact that it certainly hadn't been reconditioned. Even the paper gasket that had been fitted was made from an old postcard, and the holes in it had been made by poking a pen through it. Shall we say I was not impressed ? This time I sent it elsewhere - to a fellow that had been recommended by quite a few folks. Once again the "Precious Thing" had money thrown at it, this time it was the best part of £90. The B33 now has a working speedometer again.......but it reads about 5 mph fast. I ain't going to spend any more money on this particular item, it's now a case of "good money after bad". If it fails again, then I'll fit one of those pushbike cycle computers on it - I've got 'em fitted to the Bullet and the Guzzi ( along with the normal clock ) and they work fine.

September 2012

I suppose the only relevant thing that happened was the removal of the plastic drainpipe which served as a crutch carrier. The bike itself has given no problems, but there again, I haven't exactly been doing a vast amount of miles. . . only 2197 between MOTs.

September 2013

The B33 again has not given me any trouble. This is the year I got my new hip joint ( January 9th ) so does this mean I used the B33 more ? I'm ashamed to say I've just looked in my diary and I only took the bike out ten times over the course of the year.

September 2014

Right, so maybe this year the B33 will get a bit more use. Well - for some time the bottom end had been making a rumbling noise. The sort of noise you get when the main bearings are worn out. Now seeing as this bike had new main bearings less than 10,000 miles ago, it would seem unlikely that they had gone, and besides the frequency of this noise was at about a quarter engine speed. Now the timing side idler gear runs at a quarter engine speed and the bronze bush was a tad worn. So I pulled the timing side off, fitted a new bronze bush, reamed it to size, then put everything back together . . .and the noise was still there. Only thing to do now was take the engine out and split the crankcases. Oh dear - that doesn't look right.

It first looked like the hardening had failed on one of the nine rollers in the timing side bearing. I did a bit of research and found that particular bearing was manufactured in China, so this time I paid a bit more and ordered "better" bearings. I decided to change all three bearings ( a roller and a ball on the drive side, and a roller on the timing side ) whilst I had the engine apart. Now I'd noticed a fair bit of end float on the crank - like about .070" end float. Time to fit a .070" shim on the crank in order to hold the timing side bearing central. Even with the shim fitted there was still .070" end float. . . .only it wasn't end float it was the flywheel hitting the side of the crankcase. In the end it needed a .200" shim - that's 5mm in new money. Maybe the hardening hadn't failed on the original bearing, the roller may have only been running along half of its length.

Anyway, the new bearings are fitted and running nicely, and whilst I had the primary side off I fitted a gearbox sprocket that was four teeth bigger . . . that was a mistake, the engine did not have the power to pull gearing that tall, so off it came and a 19 tooth sprocket went in its place - that's two teeth bigger that what was originally on there, and it pulls that just fine.

I treated the B33 to a pair of Gold Star touring cams - this keeps the bottom end torque, but gives a bit more pep in mid range. Also, it sounds a lot crisper on the pick up, but has sadly lost the lovely over-run sound when you shut the throttle.

The "Precious Thing" - the Smiths Chronometric speedometer has developed the habit of not recording on the trip meter. Occasionally it will get to seven tenths of a mile and then sit there until it decides to move again. Luckily I have fitted a pushbike "computer" type speedo - a case of having to because when you change the gearbox sprocket it alters the wheel to cable ratio - one of the disadvantages of not running the speedo drive off the wheel. I'm afraid to say the Precious Thing will not be having any more money spent on it.

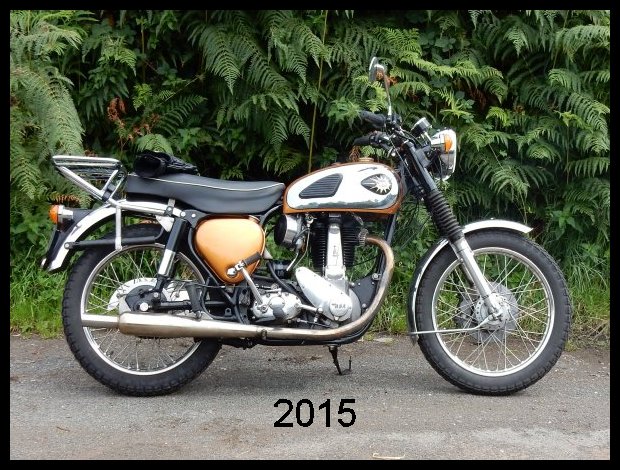

September 2015

The B33 has not been running as well as it could. Compression was down, and when I pulled the top end off the bore was seriously glazed and the piston had seizure marks on it. One rebore and new piston later and I thought all would be well. I managed less than three miles before the new piston nipped up. I checked the piston to bore clearance and found it was only around 2½ thou. The bore was honed out to give around 6 thou clearance - it still nipped up. In the end I put the original gearbox sprocket back on and refitted the original cams. The timing marks on the half time pinion were not all that clear - there's a chance I could have been running with the valve timing out.

I will run the original spec engine until I get the rear disc brake fitted and working, then I will look to fitting a Gold Star engine.

September 2016

I make a start on fitting a rear disc brake. Using a Triumph Bonneville rear hub and an alloy sprocket blank - the disc is the same as the one on the front.

The calliper is a Brembo unit from a BMW.

An alloy bracket carries the master cylinder.

Another piece of aluminium is used for the calliper carrier.

The wheel was built with stainless steel spokes and a stainless steel rim. I did have a spoke break, but that was soon fixed.

So far the disc has performed well. It's certainly a lot better than the original drum brake.

Maybe now I can think about fitting a Goldie engine.

I noticed the clutch felt a bit "notchy", so I pulled it apart. Two of the friction plates had worn away all of the friction material and had started wearing the metal.

Now it seems the friction plates for this particular clutch are no longer made, which is bad news for anyone who has a Tony Hayward clutch like mine.

I ended up buying a new clutch drum and clutch plates - the plates are commercially available, so I shouldn't have this problem again.

August 2017

The new clutch I fitted last year ( see above ) turned out to be waste of money. No matter how it was set up it would grab. This made for a most unenjoyable riding experience, so it was time to take it all off and fit the original four spring BSA / Triumph clutch. Luckily I bought a complete primary drive set up when I first built the bike. I did this "just in case" the belt drive failed. As it turned out, the belt drive was fine, it was the clutch that wouldn't work. It seems BSA knew what they were doing in the first place.

August 2018

Well it looks like the B33 will be getting a Goldie engine. I did enquire about a Pearson engine, but is seems Phil is no longer doing them. Plan "B" was those nice people over in Holland, but when I came to enquire . . . their website was down. Right - plan "C" John Cronshaw Racing. I'm currently waiting for the phone call to say my engine is done . . . then it will be time to think about getting an electric start. Let's face it, I ain't getting any younger, and my "good" leg has "had it's moments" shall we say ? I believe the Hipster term is 'Future Proofing"

Y'know - I never took a single photograph of the B33 this year. . . .or if I did, I can't find one. ( Actually, I never took any of the Bantam either, but that's understandable )

October 2019

Well, like I said, a Goldie engine is now fitted to the B33 . . .can I still call it a B33 ? I think from now on it will be called a Goldie - albeit a 600cc touring Goldie with an ABSAF engine fitted. The engine went straight into the frame with no hassle at all. The petrol tank had to be raised a bit because the angle of the new Mikuni carburettor meant it stuck up a little more than the original Amal. The engine has now done over 2000 miles and it does all that I wanted it to do - OK, so it was expensive, but I'd sooner have a bike I like than money in the bank.

August 2020

Like I said, the Goldie went and had an electric start fitted. It was a 200 mile drive over to drop the bike off, then 200 miles back home, followed by another 400 mile round trip bringing the bike back home. I went to put the bike in gear in order to roll it off the trailer, but for some reason I could only find first gear - no worries - I'll look at that tomorrow. All I wanted to do after the trip back was put the kettle on and have a rest.

Right - time to take the bike out on test. Oh dear - it seems it only has one gear now. A ten minute job to take the end of the gearbox and have a look. It hadn't been indexed correctly. A simple fix, but it didn't fill me with confidence about the rest of the work done on the bike. The first real run the bike went on was to Birmingham city centre and back - a journey of less than thirty miles. As I was getting closer to home I noticed the charge warning LED was flashing. I put the test meter on the alternator leads and it read less than 15 volts, as opposed to the 30 or more it should have read. I took the primary side off . . . . and the alternator stator was burnt to a crisp. The stator to rotor clearance had not been set and the rotor was rubbing on the stator. Just for good measure all the burn resin off the stator had stuck to the clutch plates, making the clutch inoperable. I fitted a new rotor and stator, and used a plastic pop bottle as a gauge for setting the rotor to stator clearance - something that should have been done by the 'experts' who fitted my starter motor. The clutch plates were removed and washed at the same time.

Hoping that this had now sorted any

problems out, I carried on using the Goldie. It was whilst riding up

alongside the Severn estuary toward Gloucester that I felt an almighty knock

from somewhere inside the primary chaincase. I had a horrible feeling it

was the starter chain snapping . . . it turned out I was correct.

Pressing the button just resulted in the starter motor spinning, but not turning

the engine over. Now do I ride the bike home, knowing there's a chain

lying in the chaincase, which could at any moment jam behind the clutch drum

causing the wheel to lock ? Or do I wait for the AA to come and pick me up

? I chose to ride back home - at a steady pace. Once again I

took the primary side off. There was minor damage to the teeth on both the

clutch drum and the engine sprocket, but the primary chain was a wreck. At

least half a dozen rollers had split off it and were also lying in the

chaincase.

I suspect the starter chain snapped because the bearing on its idler pulley had been contaminated with the burnt resin from the destroyed stator - when I took the bearing off, it did feel a little rough when I spun it. Considering this is spinning at roughly three times the crankshaft speed, you want it as free as possible. From an engineering point of view, I don't like two chains running side by side with nothing between them, but apparently mine was the only incident of a snapped starter chain that the people who fitted it had ever heard of. . . .maybe you know different. Anyway, I put it all back together with a new starter chain, a new primary chain and a new outrigger bearing . . . . and so far, it's been fine . . . .but we're only halfway through the year.

December 2021

Well because the Goldie also had a new clutch, it meant there was no shock absorber fitted anywhere along the transmission. If my bike had been a "normal" Goldie rather than an alternator model, then there would have been a face cam shock absorber on the end of the crank shaft. The alternator model had the shock absorber fitted in the clutch centre. I contacted NEB, the folks who made the clutch, and they do not make one with a cush-drive centre. OK - I'll fit a rear wheel with a rubber cush drive. The rear wheel from a Suzuki could be made to fit - OK, so I would lose the disc brake but the Suzuki brake would still be better than the original BSA item ( Yet the same brake on my B31 is fine ). With a bit of fettling, the new wheel was fitted.

I took the Goldie on holiday down in Cornwall, and on the Friday before I headed back home I decided to visit Land's End. It was whilst going down the A30 that I heard an almighty bang from the primary side. I first thought it was another starter chain snapping, but this time it went one better and snapped the primary chain. The AA were very prompt and efficient in getting me and the Goldie back to the campsite. If it had happened on Monday rather than Friday then it would have been a rather long recovery back home, where I would have swapped the Goldie for something else and carried on with my holiday. I have now lost all faith in the Pearson electric start conversion - two chains running side by side, and a thinner primary chain fitted - no thanks.

Having sorted the chain problem out, the Goldie had another trick up its sleeve - a rear wheel puncture. This time it came back home on my own trailer . . . after Andy rode the thirty odd miles back and picked up my trailer. The Goldie's been on a few holidays since, and has remained trouble free . . . . long may it continue.

November 2022

This year has seen the Goldie take part in the National Road Rally, where I managed to get the "Daytime Gold" award. The Goldie covered just over 450 miles that day, in some rather wet weather, and never missed a beat. It just goes to show, not all Goldies are fair weather bikes that get very little use.

November 2023

The Goldie went down Cornwall in June and covered quite a few miles - all without any hassle. As for the rest of the year - I'm embarrassed to say that since that holiday in June the Goldie hasn't been out. Why ? Well since buying an A10 - I seem to be riding / working on / fettling, that bike instead.